As a global leader in contact lenses, we help improve the way people see each day.*1

But our work doesn’t stop there. We thoughtfully design our products and packaging† to make efficient use of resources while working to reduce our carbon footprint.‡§1

Here at CooperVision, we’re taking steps in our manufacturing and distribution to operate more sustainably where possible. We are striving to eliminate waste and unnecessary packaging to reduce our environmental impact. By facilitating the responsible sourcing of materials,2 reusing waste where we can|1 and starting to offset waste from our products and packaging that cannot be yet reclaimed, we’re taking strides to improve the well-being of our planet. ¶1

Together with our customers, our partners and beyond, many small acts today count toward a brighter tomorrow for People + Planet.

We design—and continuously redesign**—to reduce our carbon footprint.‡§1

We thoughtfully design our products and packaging† to make efficient use of resources while starting to reduce our carbon footprint.‡§1 From our products to our facilities and our processes in between, we’re purposeful in the choices we make today toward a greater collective impact tomorrow.

We design for recyclability, engineering products and packaging to work with community recycling programs wherever possible.

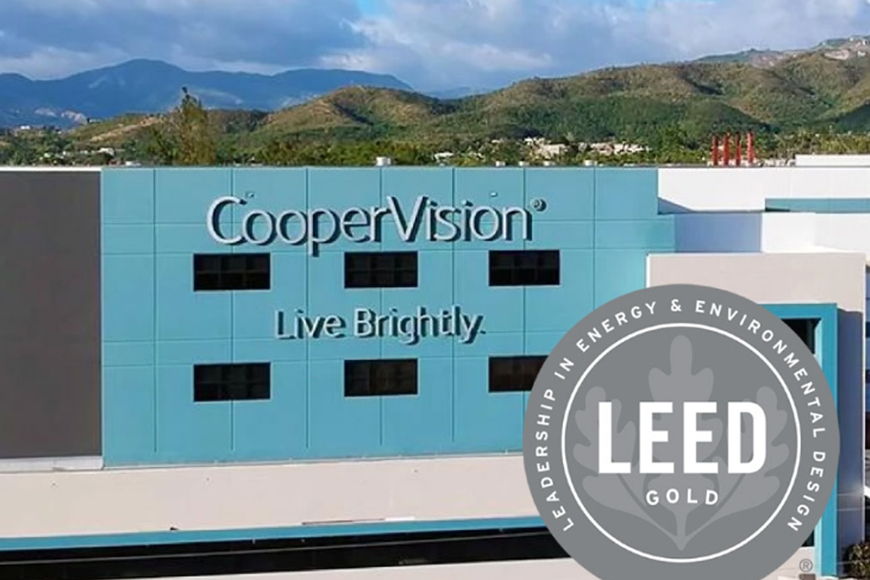

We build facilities powered by renewable energy1 and develop processes† to intentionally reduce our footprint.‡§1 We design—and continuously redesign† —to produce less waste.††3

We collaborate and innovate, embracing our ingenuity to care for our planet and each other.

At CooperVision, we’re passionate about our role as a global citizen, empowering our employees to champion sustainability—no matter how small the act. Together with eye care professionals and contact lens wearers, we can all take steps to embrace sustainable actions today to help protect our future.

But we’re about so much more than contact lenses. That’s why we partner with international organizations and communities to help us reduce our environmental footprint1 and make a positive difference. All of this is made possible by people with passion, innovative thinking and a drive for action.

Through our collective ingenuity, we can take strides to improve the well-being of our planet, together.1 And we invite you to join our journey toward a brighter tomorrow.

We’re taking steps† to conserve limited natural resources‡‡1 and are exploring ways to bring renewables§§ into our manufacturing operations.¶1

We work with partners to collect our manufacturing waste, recapturing resources and giving them new life when possible.|1

By starting to offset waste from our products and packaging that cannot yet be reclaimed, we’re taking strides to improve the well-being of our planet.¶1

FEATURED STORIES

Here at CooperVision, we’re proudly taking steps to operate more sustainably and striving to minimize our possible environmental impact.

Through our Sustainability Innovator Series, we’ll share stories of people in a wide range of roles throughout our organization who have contributed to our sustainability efforts, big and small.

We’re embracing Plastic Made Better by starting to purchase ISCC PLUS-certified plastic.¶¶***2,5,6 together.

In doing so, CooperVision is committed to achieving a higher standard for how plastics are made.

Through our partnership with Plastic Bank, we offset a portion of our plastic footprint.2

To date, our partnership has prevented the equivalent of hundreds of millions of plastic bottles†††8 from entering the world’s oceans and improved the livelihoods of thousands of collection members in hundreds of communities.2,8

Explore more and see how we're taking steps towards a brighter tomorrow.

* Combination of 2022 market research based on global volume data and internal estimates.

† Refers to continuous manufacturing improvement processes undertaken by CooperVision to increase efficiency.

‡ Carbon footprint is limited to Scope 1 and 2 emissions, defined as: Scope 1 emissions are direct emissions from owned or controlled sources. Scope 2 emissions are indirect emissions from the generation of purchased energy.

§ CooperVision's 2022 Environmental, Social, and Governance Report.

| CooperVision's 2020 Environmental, Social, and Governance Report.

¶ Refers to CooperVision's plastic neutrality initiative with Plastic Bank.

** Refers to continuous manufacturing improvement processes undertaken by CooperVision to reduce its Scope 1 and 2 carbon emissions.

†† Waste associated with the manufacturing of contact lenses.

‡‡ Natural resources are defined as but not limited to water, nitrogen, natural gas and other organic compounds.

§§ Renewables are defined as materials or energies that can be sustained indefinitely because of inexhaustible supplies or new growth.

|| CooperVision uses renewable materials and energies in its manufacturing operations.

¶¶ According to peer-reviewed papers, polypropylene (PP) made using renewably sourced inputs yields a lower carbon footprint. Coopervision's plastic supplier has found that manufacturing PP using fossil-based inputs produces 1.63 kg CO2e/kg PP whereas manufacturing PP using plant-based inputs produces -0.82 kg CO2e/kg PP.

References:

1. CVI data on file, 2023.

2. CVI data on file, 2023. CooperVision Supplier Code of Conduct.

3. CVI data on file, 2023. Manufacturing sites: Costa Rica, Hungary, New York State, Puerto Rico and Southampton, UK.

4. CVI data on file, 2023. Cradle-to-gate assessment of our supplier's biorenewable input.

5. Narayan, R. (2011). Carbon footprint of bioplastics using biocarbon content analysis and life-cycle assessment. MRS Bulletin, 36(09), 716–721. https://doi.org/10.1557/mrs.2011.210.

6. CVI data on file, 2023. Cradle-to-gate assessment of renewable bioinput carried out by our supplier of plastic polymer to CooperVision.

SA10345_1